Manufacturing

DI Squared solutions help organizations use data to optimize processes,

improve supply chain, and better serve customers.

Launch OEE App

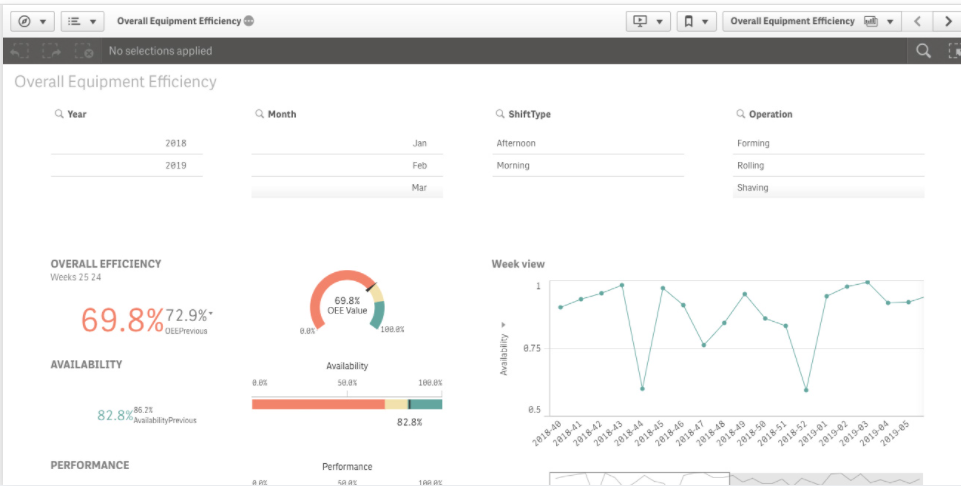

Overall Equipment Efficiency (OEE) analysis is critical to understand the uptime in a production site and improve throughput.

Qlik's associative technology helps manufacturers make sense of 3 important KPIs: availability of equipment, operation performance, and production yield. This demo app provides a comprehensive overview of a Mills production line, delivering insights and diagnostic capabilities in order to improve performance over time.

Key Performance Indicator (KPI)

A Key Performance Indicator is a measurable value that demonstrates how effectively a company is achieving key business objectives. Organizations use KPIs at multiple levels to evaluate their success at reaching targets. High-level KPIs may focus on the overall performance of the business, while low-level KPIs may focus on processes in departments such as sales, marketing, HR, support and others

Manufacturing

DI Squared Manufacturing solutions pay special attention to manufacturing Key Performance Indicators (KPI)

On-Time Delivery

This metric measures the percentage of orders delivered on-time. The metric is often tallied monthly for statistical relavance and the aim should be 100% fulfillment.

Schedule Attainment

This KPI tracks how often the production team meets the target level of production and provides an important way to set performance benchmarks, fine-tune work order delivery time estimates, and make sure that performance issues aren’t causing costly delays.

Total Cycle Time

The total cycle time measures the time it takes for a customer order to start and finish the entire production process all the way to shipping. It represents the full time required to convert raw materials into finished goods from one end of the line to the other.

Capacity Utilization

If a machine is producing goods at an ideal cycle time, it is said to be running at 100% capacity.

When running slower or anytime a machine is idle, this percentage will drop, indicating available capacity and slack in the system. This is a great KPI to understand the facility’s ability to scale production or institute more agile job scheduling.

Customer Return Rate

As a measure of performance, increasing customer returns might indicate a flaw in the production process or a missing step in quality control. The costs of customer returns can quickly escalate due to the rework required and the effort and cost of reverse logistics.

Planned Maintenance % (PMP)

This KPI is a combination of calculating the percentage of scheduled maintenance vs. planned maintenance plus all the emergency maintenance required to address breakdowns.